LOWER

Step-by-step guide to elevating your being ~ we're interested here in a common template to cut the cost of assembly and operation, using everyday materials and tools. The base built, all else will follow.

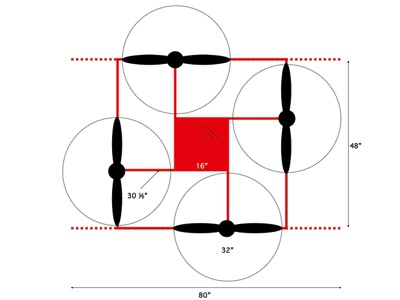

The prototype featured is a proof-of-concept demonstrating how an adult ~ if test-pilot Colin Hilton could be considered as such ~ can be accommodated. Using leftover parts from a previous effort (5.5kW motors and 32" propellers) however the airframe will be able to raise only a full-sized mannekin.

Basic material includes one-sixteenth inch-square aluminium tubing, 1.50 mm aluminium sheet and inch-thick low-density PU insulation foam. Parts are joined with adhesive and 4 x12 mm pop-rivets and finished in Post Office red.

The internal arms which define the centre-section are cut to a little less than stock 31" to include M6 thread tube-inserts at either end. Each corner of the airframe perimeter is fitted with 3-way 25mm tube-connectors, supporting four stubs of variable length (but 6" in the case of the present build).

Stub legs include M6 inserts in support of an optional set of skids of the same section, that terminate in the prototype in horns of a short length. Fashioned in a local workshop, these are fixed using short lengths of square wooden spar.

T-motor's U13 power-units feature 4 x 4 mm mounts which are set square: two on one side fixed along the centreline of the tubing and the overhanging pair fixed to 1" angle-alloy of a similar thickness that used elsewhere and cropped to the 100mm outline of each motor.

Although the propeller-disks are offset to direction of travel, this is of no consequence as the base forms a simple source of lift independent of the upper drone. Consequently motors run at a constant RPM such that speed controllers, batteries and other electrical devices are less prone to failure.

31st August 2021